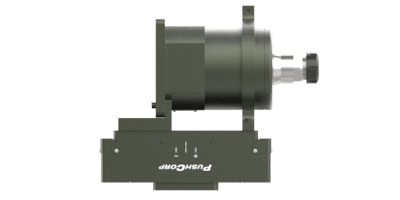

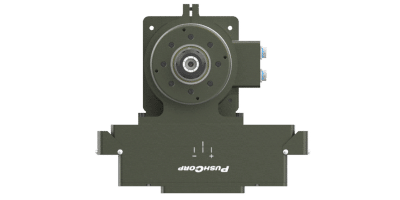

SM0612

High-Torque, Robotic Servo Spindle

The PushCorp SM0612 high-torque servo spindle is an ideal solution for robotic, material-removal applications such as:

- Robotic Grinding

- Robotic Sanding

- Robotic Polishing

- Robotic Deburring

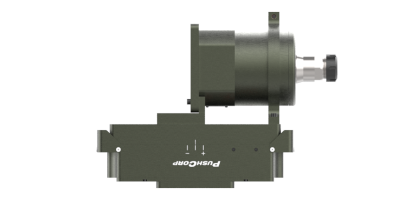

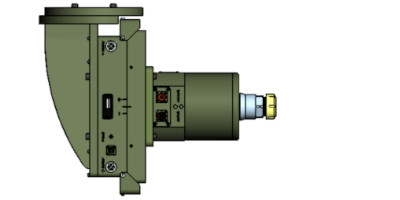

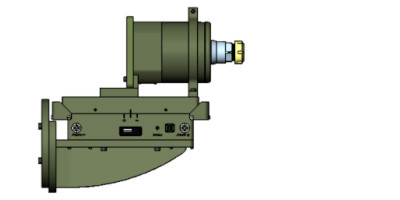

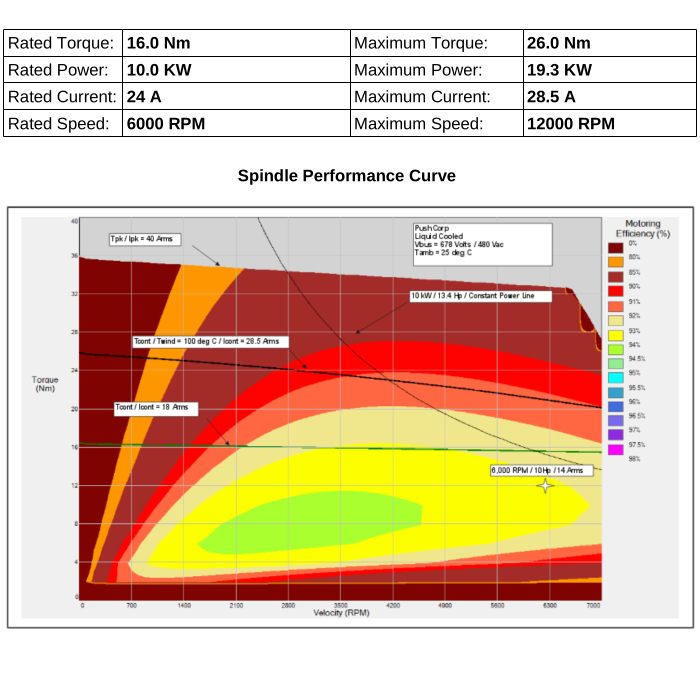

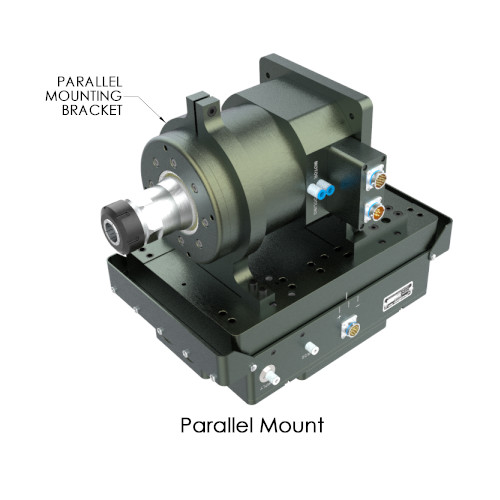

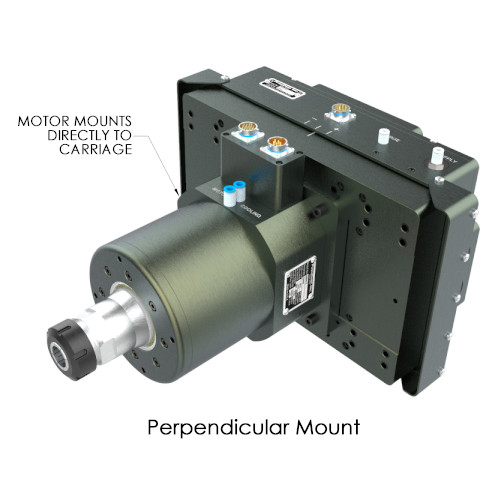

The SM0612 features a powerful 12.0 hp [9.0 kW] servo motor that provides constant speed. This equipment is designed to mount in a parallel or perpendicular orientation on the AFD620, AFD82, AFD1240, and AFD92 force compliance devices. As a result, it has never been easier to program beautiful and consistent surface finishes.

The SM0612 may also be mounted directly to the robot with no force compliance device. This opens the door for rigid applications such as routing and deflashing.

The SM0612 has been developed as a lower-priced alternative to the STC0612-BT40. The SM0612 uses the same 6,000 rpm high-speed motor from the STC0612 but without the automatic collet release. Instead, a manual "ER" Series collet is used to clamp the tool shaft. This means that operator intervention is required when the media needs to be replaced. For applications where the abrasive media or the tools have a long life, the manual collet is the ideal solution.